Introduction Bulletproof Back Plate

Silicon carbide ceramics have excellent properties such as high hardness, strong impact resistance and good wear resistance. Therefore, they have been widely used in various fields of modern industry.The silicon carbide bulletproof back plate is prepared by the sintering process, and the strength is much higher than that of the warhead, and the warhead breaks up immediately after impact, allowing it to release its kinetic energy quickly.

Tests have shown that this kind of ceramic is superior to alumina ceramics in the protection of light weapons ammunition and tail stable shelling armor-piercing, and its price is lower than that of boron carbide ceramics. Therefore, in recent years, the United States and other developed countries have developed them into bulletproof ceramic inserts plate to replace alumina (Al2O3) inserts plate for body armor equipment.

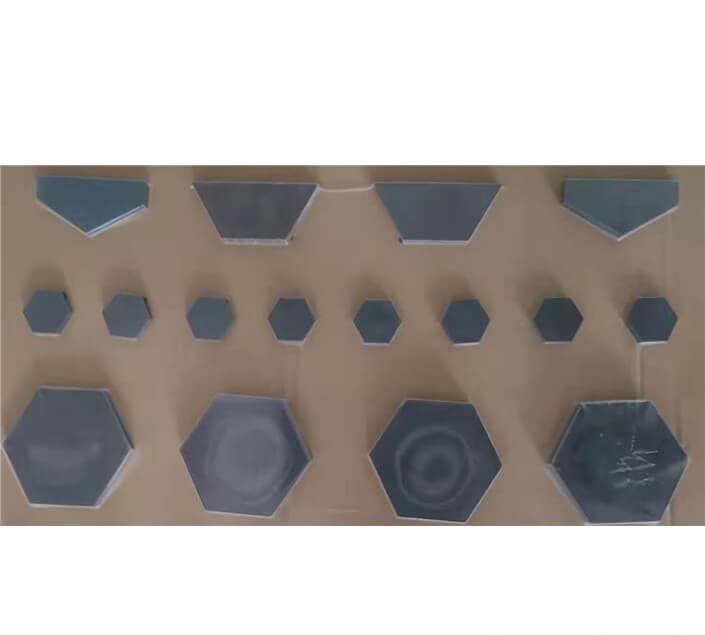

Characteristics Bulletproof Back Plate

We have researched and developed silicon carbide bulletproof back plate with the advantages of light weight, high hardness, good bulletproof and many other performance. Synthetic silicon carbide ceramic bulletproof insert plates for new type of single soldier bulletproof equipment.Tested by the National Special Protective Clothing Quality Supervision and Inspection Center, the various bulletproof performance indexes meet the requirements of military standards under the premise of weight reduction.Through the troops try on fitting, the test officers and soldiers evaluation is good.In 2009, it passed the scientific and technological achievements appraisal organized by the General Logistics Department. The anti-elasticity is comparable to that of the internationally renowned ceramic bulletproof armor manufacturer, filling the domestic gap.The successful research and development of silicon carbide bulletproof insert plate has realized the characteristics of high performance, low cost and light weight, and promoted the application of silicon carbide ceramics in the field of individual soldier bulletproof. It is of great significance to improve the protection ability of individual soldier bulletproof equipment of our army and public security police and enhance the combat effectiveness.In addition to single-armor bullet-proof vests and bullet-proof helmets, SiC anti-ballistic ceramics can also be used for bulletproof armor of tanks, armored personnel carriers, etc., It can also provide protective equipment for field tents, oil transport vehicles, ships and helicopters.

Technical Data Sheet of Bulletproof Back Plate

| Item | Unit | Data |

| Max Working temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | <0.1% |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal conductivity | W/m.k | 45(1200℃) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid alkaline-proof | Excellent |

Related Products:

This post is also available in: Arabic French German Indonesian Italian Japanese Korean Portuguese (Portugal) Russian Spanish