Introduction SISIC Ceramic Protection Tubes

At a temperature of about 1300 degrees, ordinary stainless steel or alloy stainless steel has been difficult to withstand for a long time. At this time, some ceramic materials will be selected, and the silicon carbide ceramic thermocouple protection tubes will be suitable.

Silicon carbide products have high temperature strength, light weight, good heat conduction, small heat storage,long life and other excellent performance.They are widely used in ceramics, petrochemical, aerospace and other industrial sectors. For example, it can be used in the manufacturing of ceramic kiln furniture. The use of SiSiC kiln tools can significantly improve the loading efficiency and energy saving. Besides, the silicon carbide thermocouple protection tube can meet the continuous demand in the field of high-temperature measurement with its superior corrosion resistance and high thermal conductivity.

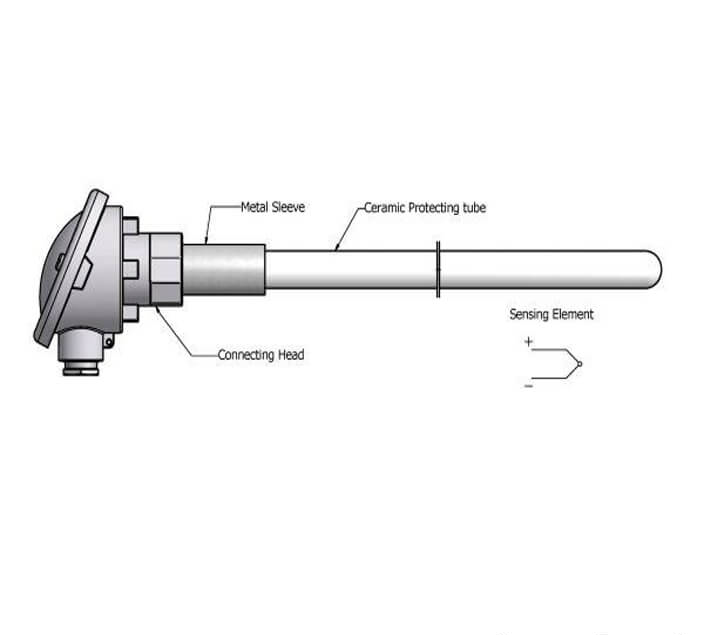

As a temperature sensor, the thermocouple protection tube is usually used with temperature transmitter, thermostat, temperature indicator, etc. It is called the process control system. With this system operation, the thermocouple protection tube can be used to test and control all the temperatures of fluid, steam, gas, surface of solids, etc.whose temperature is between 0-1800 degree Celsius during various production processes.

Characteristics SISIC Ceramic Protection Tubes

As a thermocouple manufacturer, our company specializes in the production of ceramic thermocouple protection tubes. They must meet the requirements before delivery,and the quality is guaranteed. Compared with the products of similar companies, the service life can be greatly improved by more than 50%.

When selecting a thermocouple protection tube, the following factors should be considered: temperature, atmosphere, flow rate, corrosiveness of the measured medium, thickness of the tube, wall thickness, length, air tightness, thermal shock resistance, chemical compatibility, pressure, stress, response speed, and cost performance. We can choose the appropriate protection tube material according to the actual situation.

Since each materials has its own characteristics, it is requested to be easy installed, aseismatic with large temperature testing range and high mechanical strength considering of both tested items such as the item’s temperature, flow velocity, corrosivity, etc. and tubes including diameter, thickness, length, mechanical stress, thermal shock capacity, price, etc. The materials of thermocouple protection tube could be chose according to the situations and needs.

There is a strong capacity of silicon carbide thermocouple protection tube in the fields of heat resistance, Oxidation resistance, thermal shock resistance, wear resistance, corrosion resistance with chemical stability, etc. It is an ideal material of thermocouple protection tube with high performance as below.

- No obvious change of the strength under a high temperature of 3000 F degree.

- Excellent thermal shock resistance.

- Corrosion resistance with chemical stability.

- High thermal conductivity, 5 times higher than stainless material.

- High wear resistance which is 1.5 times higher than tungsten carbide material.

Technical Data Sheet of SISIC Ceramic Protection Tubes

| Item | Unit | Data |

| Max Working temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | <0.1% |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal conductivity | W/m.k | 45(1200℃) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid alkaline-proof | Excellent |

Related Products:

This post is also available in: Arabic French German Indonesian Italian Japanese Korean Portuguese (Portugal) Russian Spanish