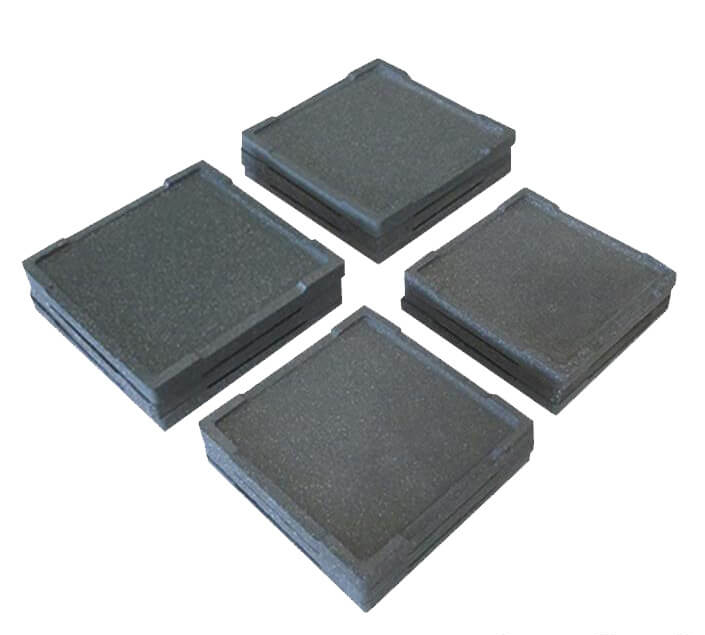

Introduction Refractory Sagger

Refractory sagger, the most widely used is silicon carbide sagger,it can be used in metallurgical, chemical, glass and other various areas,including powder sintering, metal smelting,dewatering components in papermaking industry and various wear resistance parts. (Using temperature 1380℃, working pressure 280mpa).

The common problems during using:

1.After a long period of using, a longitudinal crack appears in the sagger wall, and the sagger wall at the crack is thinner.

Analysis of the reasons: When the sagger is about to reach its service life, the wall will become thinner and cannot withstand excessive force.

2.First-use (or nearly new) sagger has a crack on the bottom edge and runs through the bottom of the sagger.

Analysis of the reasons:Put the cooled sagger into a hot heat, or when the sagger is cooling down, fast heat the bottom of the sagger, The damage is generally accompanied by glaze peeling.

Characteristics Refractory Sagger

Main features:

- Fast heat conduction: using high thermal conductivity materials, dense organization,low porosity, fast heat conduction.

- Long service life:2 to 5 times longer life for different materials compared to ordinary clay graphite saggers.

- High density:using advanced isostatic pressing process, the material is dense and uniform without any defects.

- High strength:adopted high-quality materials, high-pressure pressing, reasonable combination, good high temperature strength, scientific product molding, high pressure capability.

- Anti-corrosion: advanced material formula, effectively resist the physicochemical effect of the melt.

- Less sticky slag: less wall-mounted slag, which greatly reduces the possibility of heat-resisting effect and bursting sagger, and always maintain maximum capacity.

- High temperature resistance: using temperature 400-1700℃, different ranges are optional.

- Less pollution: the material design completely considers the relationship with the smelted metal and the process characteristics, with little or no harmful impurities.

- Metal saving: Due to the material belongs to special element, it can effectively inhibit the oxidation of metals.

- Energy Saving and Environmental Protection: Fast heat transfer can save a lot of fuel and reduce exhaust pollution. Proper resistivity, induction heating can significantly reduce reactive power loss.

- High oxidation resistance: advanced anti-oxidation mechanism, so that it can protect the graphite in the saggers.

Technical Data Sheet of Refractory Sagger

| Item | Unit | Data |

| Max Working temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | <0.1% |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal conductivity | W/m.k | 45(1200℃) |

| Coefficient of thermal expansion | K-1×10-6 | 4.5 |

| Rigidity | 13 | |

| Acid alkaline-proof | Excellent |

Related Products:

This post is also available in: Arabic French German Indonesian Italian Japanese Korean Portuguese (Portugal) Russian Spanish